Copper Tungsten Products

Copper tungsten and its alloy products are supplied by our facility located at the bulk of the copper tungsten source. They are usually available in sheets, plates, rods, discs and bars and black and cleaned wires for supports and wire cuttings. Chinatungsten Online also have the fabrication capacity to make precision machined copper tungsten parts and alloy parts according to your drawings.

Main products of copper tungsten

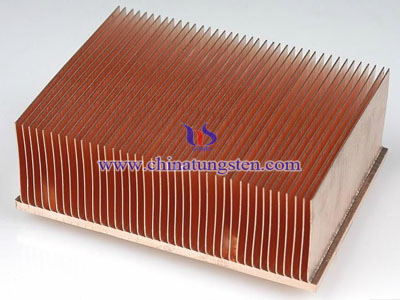

Tungsten copper heat sinks

Our tungsten copper composites to be used extensively in thermal mounting plates, chip carriers, flanges, and frames for high-powered electronic devices. With the thermal advantages of copper with the very low expansion characteristics of tungsten, tungsten copper has properties similar to those of silicone carbide, aluminum oxide, and beryllium oxide. The thermal conductivity and low expansion also make tungsten copper alloy an excellent choice even for extremely dense circuits.

The Cu-W 75 copper tungsten alloy is used extensively in thermal mounting plates, chip carriers, flanges, and frames for high-power electronic devices. As a tungsten copper material, it's a composite, so both the thermal advantages of copper and the very low expansion characteristics of tungsten can be utilized.

The combination of tungsten & copper materials results in thermal expansion characteristics similar to those of silicone carbide, aluminum oxide, and beryllium oxide, used as chips and substrates. Because of tungsten copper's thermal conductivity and expansion characteristics, copper tungsten alloy works well in densely packed circuits.

Copper tungsten resistance weldingIf you can't stand the heat resistance welding isn't for you. Luckily, electrodes made from our copper tungsten composites perform even under the most extreme conditions. High-thermal and electrical conductivity along with the ability to reduce heat-balance problems make our copper tungsten composites excellent choices for die inserts and electrode facings, flash and butt welding dies, and hot upsetting.

The high physical and mechanical properties, as well as the thermal and electrical conductivity, of refractory metal composites make copper tungsten alloy very suitable for die inserts and electrode facings, flash and butt welding dies, and hot upsetting. They can also solve heat balance problems.

Copper tungsten electrical contacts

The Cu-W 75 copper tungsten materials can be also used in oil-filled devices, air and gas circuit breakers, contactors, and high voltage switch gear. Some common applications are:

Arcing contacts and plates

Arc runners

Current carrying members

Blade facings

The high electrical and thermal conductivity of tungsten copper alloy allows a cool, effective transfer of power, while the excellent arc-resistance properties of tungsten copper minimize arc erosion and transfer problems. These characteristics can be varied by composition more silver or copper yields higher electrical and thermal conductivity, while a higher refractory metal content results in superior arc erosion properties. We offer a variety of composites to meet your demands. Regardless of the environment (oil-filled devices, air and gas circuit breakers, contactors, high voltage switch gear) or the application (arcing contacts and plates, arc runners, current carrying members and bladefacings), you won't be disappointed in electrical contacts made from our copper tungsten composites.

Copper tungsten EDM and ECM

Our copper tungsten composites are used worldwide for electrical discharge machining (EDM) and electrochemical machining (ECM) electrodes. All composite material is manufactured by the press, sinter, and infiltrate process; adhering to strict quality checks every step of the way. You can rely on the quality of our tungsten composites to provide consistent, homogeneous materials that yield high and even burning rates

Tungsten copper alloys are used worldwide for EDM (Electrical Discharge Machining) and ECM (Electrochemical Machining) electrodes. All material is manufactured by the press, sinter, and infiltrate process. Virgin tungsten powders are used, resulting in a consistent homogeneous material giving high and even burning rate. Tungsten copper is used in plunger/sinker applications where intricate definition is required, especially in tungsten carbide.